RAS

Making Welding in East Asia More Efficient and Ergonomic.

Kemppi, a Finnish manufacturer of welding equipment, challenged their student design team from Stanford University, Aalto University, and the Kyoto Institute of Technology to create a significantly innovative piece of welding equipment that would allow European manufacturers of welding equipment to penetrate the Asian welding market.

Upon researching their market, the student team began to realize that East Asian welders operate differently from European welders; they hold a hand-held mask in their left hand and a welding tool in their right, making it difficult for them to control or hold much else. Not only that, but welding tools in the East often don’t have connectors for remotes, making real time control of welding parameters unwieldy and troublesome. Unfortunately, this lack of control also comes with a dip in product quality.

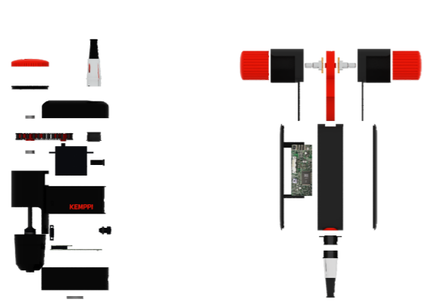

To combat these issues, the student team created the RAS (Remote Adjustment System) which consists of two parts: the RAS Hat and the RAS Remote Control. The RAS Hat is used to add a remote control function to welding machines that hadn’t initially supported the use of remote control. The RAS Remote Control uses Bluetooth or Zigbee to connect to the RAS Hat, allowing welders to control welder parameters remotely and with ease. Both of the RAS components work together to create an ergonomic and efficient welding work-space where welders can create higher quality products with ease.

Year:

Corporate Partner:

Design Team:

2009–2010

Kemppi

Aalto University

Sirja Luomaniemi Riku Nagasaki

Antti Sonninen Vi Van

Kyoto Institute of Technology

Sho Hirakawa Seiki Ishii

Wataru Mito Keita Nishiyama